Metal vs Composite Pipe and Cable Ramps: Which is Better for Your Job Site?

If you’ve ever worked a construction site, laid cable at an event, or managed an industrial facility, you know what a pain – and danger – hoses, pipes, and cables can be. Tripping hazards. Damaged lines. Makeshift plywood ramps that barely hold up. That’s where pipe ramp protectors come in—and not all are created equal.

Today, we’re comparing two common types of hose ramps: metal (usually aluminum or steel) and composite (plastic or rubber). If you’re asking yourself, “Which one is right for my job site?”—you’re in the right place.

Let’s break it down.

What Are Cable, Pipe, and Hose Ramp Protectors?

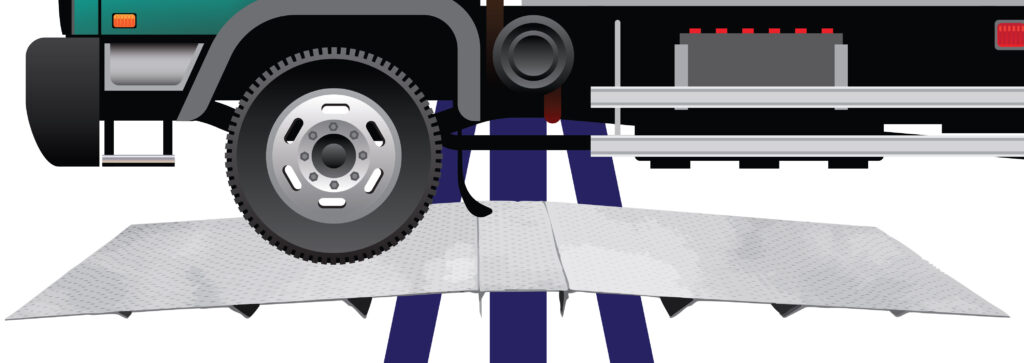

Hose ramps (also called drive over pipe ramps or heavy duty hose protector ramps) are exactly what they sound like: raised ramps that let vehicles and foot traffic pass safely over pipes, hoses, and cables without crushing them.

They’re essential in work environments like:

- Construction sites

- Oil and gas fields

- Water treatment facilities

- Municipal road projects

- Emergency scenes (fire departments love these!)

These ramps protect your gear and your crew. No more ruined hoses, no more workers tripping over a bundle of conduit–just smooth, protected access.

Metal Hose Ramps: Tough as Nails

Let’s start with metal ramps, like the aluminum hose ramps offered by HandiRamp.

Pros:

- Unmatched Durability

These things are built to last. Fabricated from high-strength aluminum, HandiRamp’s models can withstand years of use in the harshest conditions—rain, mud, snow, UV exposure, you name it. - Superior Load Capacity

Standard models support up to 750 lbs, ideal for foot traffic and light vehicles. Need more? They can be customized to handle heavy-duty trucks, forklifts, and industrial equipment. - Non-Slip Safety

With a patented raised-button traction surface, aluminum ramps provide excellent grip even in wet, oily, or icy conditions. - Versatile & Portable

Metal ramps are foldable, stackable, and easy to deploy, making them great for temporary or mobile operations. - Weather Resistance

Metal ramps aren’t going to warp or degrade in the sun. They hold up year after year—no cracking, no rotting, no drama.

Cons:

- Heavier Than Plastic

Although aluminum is lightweight for a metal, these ramps still weigh more than your average rubber ramp. If you’re constantly moving them solo, you’ll feel it. - Price

They’re a bigger investment up front, but you get what you pay for in performance and longevity.

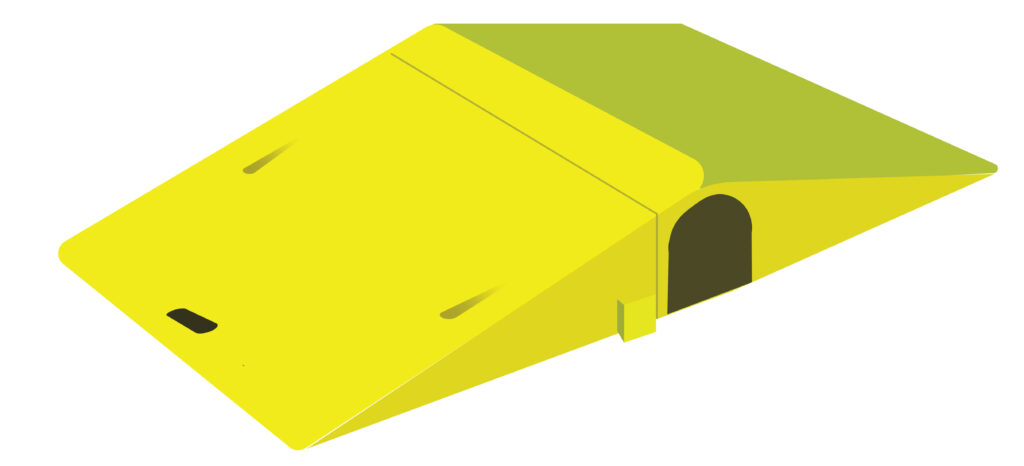

Composite Hose Ramps: Lightweight and Easy

Composite ramps are typically made from rubber, plastic, or a blend of polymer materials. They’re commonly seen at music festivals, parking lots, or event setups where temporary ramp-over-pipe solutions are needed.

Pros:

- Lightweight

These are easy to carry, set up, and move. Great for quick setups and short-term use. - Cheaper Up Front

Composite drive-over pipe protectors are budget-friendly and accessible for smaller operations. - Basic Protection

They’re fine for foot traffic and some light vehicles, depending on the model.

Cons:

- Lower Load Capacity

Even the beefier composite ramps can’t compete with steel or aluminum. If you’re running equipment over them—or even heavy pickups—they may not hold up. - Prone to Weather Damage

Rubber and plastic don’t age well. UV exposure, heat, cold, and moisture can cause cracking, fading, or warping. - Less Traction

Many composite ramps don’t offer the same non-slip features as metal ramps. That’s a serious concern when safety is on the line. - Limited Lifespan

They’re not designed for long-term industrial use. After a few seasons, they may need to be replaced.

Use Cases: Metal vs Composite

Let’s talk real-world application. When would you choose a metal hose ramp protector, and when would a composite ramp be good enough?

Choose Metal If:

- You work in construction, oil & gas, municipal services, or manufacturing.

- You’re running heavy equipment or vehicles over the ramp.

- Your worksite is outdoors, in unpredictable or rough weather.

- You want something long-lasting, even if it costs more.

Choose Composite If:

- You’re setting up a short-term event, like a concert or festival.

- Only pedestrian or light cart traffic will be using the ramp.

- You need something extremely portable and don’t mind replacing it over time.

.

What Makes HandiRamp’s Metal Cable Ramps Stand Out?

Not all metal ramps are equal. Here’s what makes HandiRamp’s drive-over pipe ramps a favorite across industries:

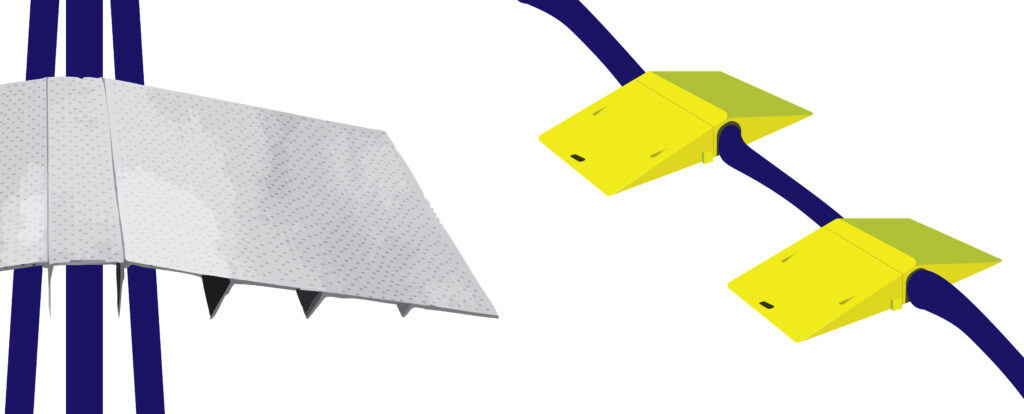

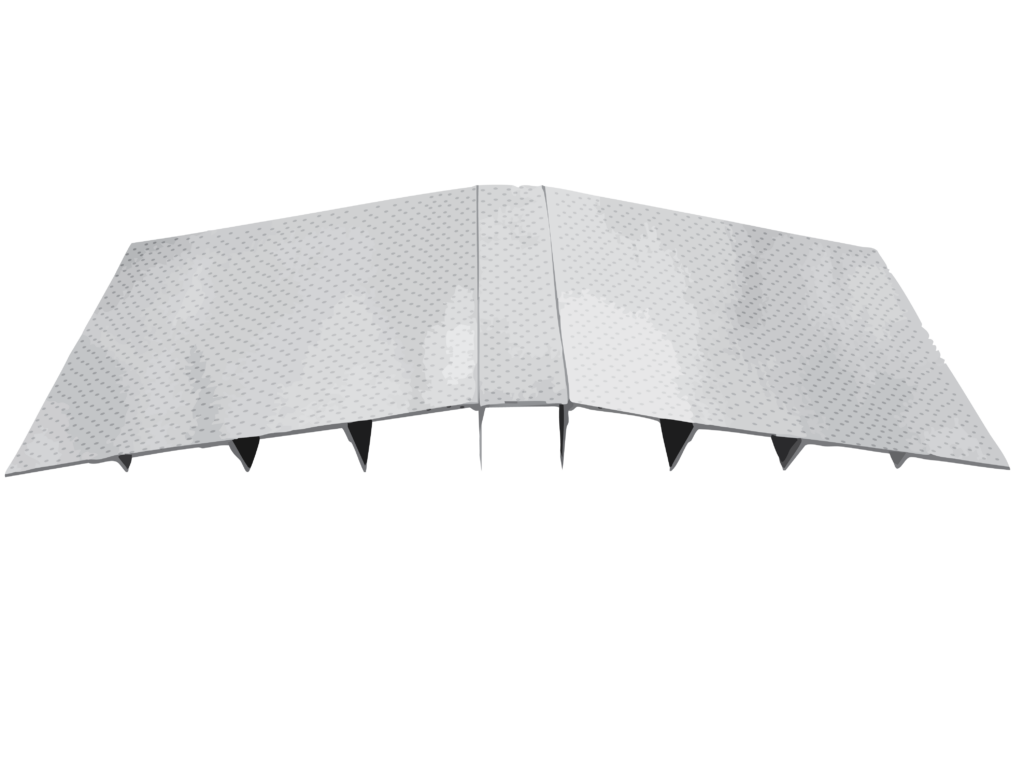

- Large center channel for cables/hoses/pipes with a standard 6 inches in diameter

- Additional side channels for running multiple lines

- Heavy-duty aluminum that won’t rust or corrode

- Foldable wings for easy deployment and compact storage

- Non-slip, raised-button surface

- Custom dimensions, weight capacities available

It’s a ramp built for serious job sites, from fire stations to drilling rigs.

Bonus: Composite + Metal Hybrid Options Some setups combine composite ramp bodies with metal-reinforced inserts for extra strength. These hybrids can be a decent middle ground, but they still don’t match the longevity or load capacity of full metal ramps.

Final Thoughts: Go Metal for the Long Haul

When it comes down to it, metal ramps—especially aluminum—are the gold standard for protecting pipes, hoses, and cables in demanding work environments. Composite ramps might be fine for quick fixes or light-duty use, but if you want a solution that’s going to last, metal’s the way to go.

Looking for a heavy duty hose protector ramp? Need a drive over hose protector that can handle trucks and loaders? Want a pipe ramp protector that won’t crumble under pressure? Whether it’s a drive over pipe protector or a reliable floor pipe protector for your facility, metal hose ramps are the answer. Forget makeshift ramps to go over pipes—get the real thing.

Need help figuring out what ramp works best for your site? Give the HandiRamp experts a call at 800-876-7267 or explore more at handiramp.com/hose_protector_ramp.htm.

Don’t risk your crew’s safety—or your equipment—on a flimsy plastic fix. Upgrade your job site with a ramp that works as hard as you do.