- Shop

- Why HandiRamp?

- Sales & Rentals

- Knowledge Base

- Decision Guides

- Case Studies

- Property Manager Enhances Building’s Value with a Portable Loading Dock Solution

- How Wrigley Field Restored Its Outfield in 2 Days with a HandiRamp Portable Yard Ramp

- Portable Loading Dock Ramp Helps Fruit & Vegetable Distributor Cut Overhead Costs

- Replacing a Dangerous Concrete Ramp With a Portable Loading Dock

- Contact Us

Case Study: Portable Loading Dock Ramp Helps Fruit & Vegetable Distributor Cut Overhead Costs

Summary

Company sees decreased wait times, less spoilage, and faster shipping with a Handi-Ramp portable loading dock ramp

About the Client:

- Southern California produce wholesaler and distributor

- Operates farmer’s market out of warehouse parking lot

- Accepts shipments directly from farmers

The Challenge:

- Relieve the delays and congestion slowing down the warehouse’s operations

- Cut shipping delays to reduce product spoilage

- Create overflow loading dock space

- Reduce congestion in shipping areas

- Increase overall throughput for entire facility

Solution:

- Stage portable loading dock ramp near Building C (see map)

- Use the ramp to provide quick access to loading equipment for local deliveries

- Relieve congestion at larger buildings when their shipping bays are full with ramp

Results:

- Drastically reduced driver wait times

- Spoilage reduced by 4-7%

- Portable loading dock makes unloading possible anywhere

- Reduced overtime expense

Introduction: How a Produce Wholesaler Used a Portable Loading Dock Ramp to Eliminate Congestion

A produce wholesaler and distributor based in Southern California approached Handi-Ramp with a question: How can we ease the congestion in our shipping and loading docks without constructing any more buildings?

The location needed to be suitable for receiving shipments from a host of local farms and orchards, and the layout of their facilities was causing a bottleneck and resulting in increased overheads.

The Challenge: Warehouse Bottlenecks Without a Loading Dock Led to Delays and Spoilage

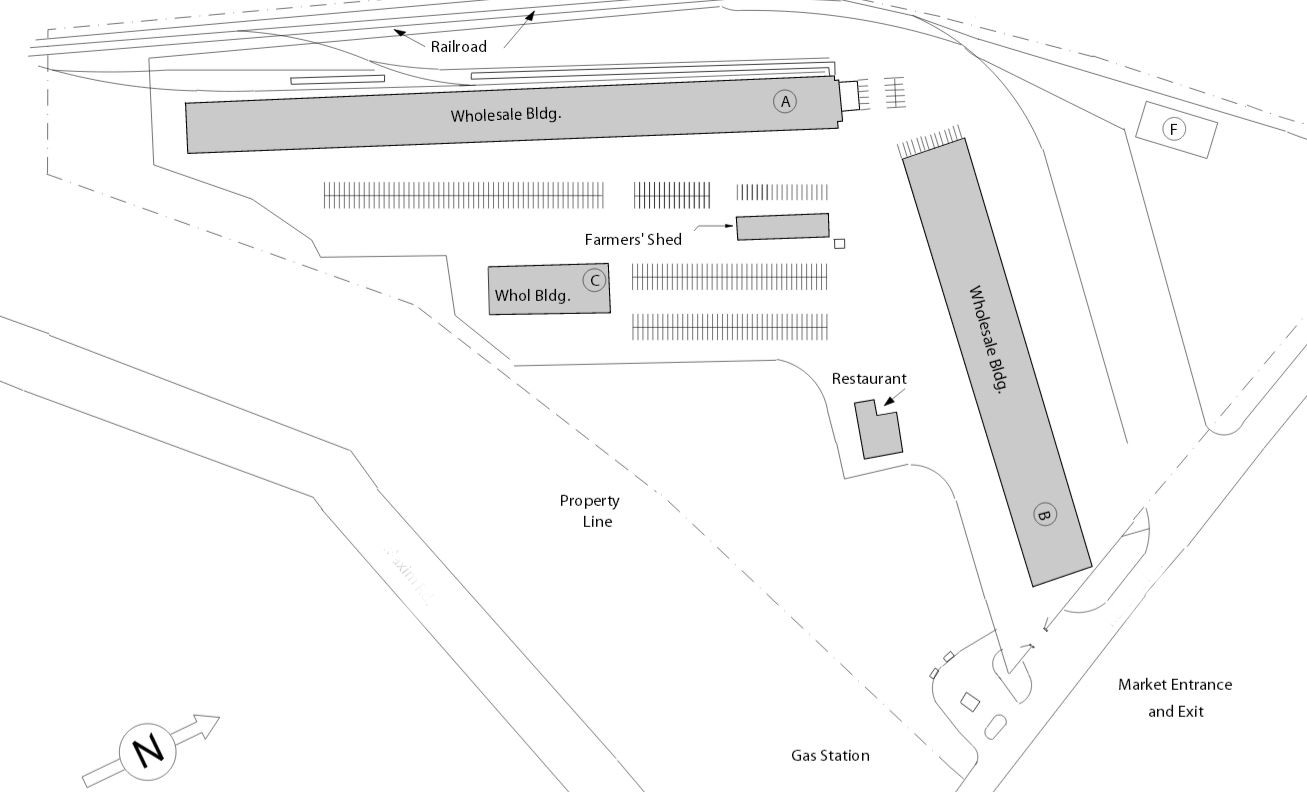

The client’s facilities comprised three buildings (marked A, B, and C on the map below) that received shipments, with building C lacking any trailer-height loading docks. Buildings A and B were fully-functioning shipping and receiving facilities with railroad access and plenty of space, but the internal location and inadequate dock design of building C made it difficult to use for quick unloading.

As a result, building C was only being used for small, local shipments and pallet stocking. This also meant unnecessary clutter and delays around the small farmer’s market in the facility’s parking lot. With forklifts hauling goods from buildings A and B to C and vice versa, the yards between buildings were hectic, unmanageable, and inefficient.

Handi-Ramp was asked to propose a practical, real-world solution to relieve the clutter and provide additional loading and unloading capacity for the client. With produce, spoilage is a constant concern, which meant the solution had to be something that could be deployed rapidly whenever the loading docks got too crowded or full with inventory.

Handi-Ramp was also tasked with finding a solution that made the farmer’s market easy to stock with the freshest produce.

Facing similar unloading challenges at your facility?

Our Solution: Creating Overflow Dock Space with a Portable Loading Dock Solution

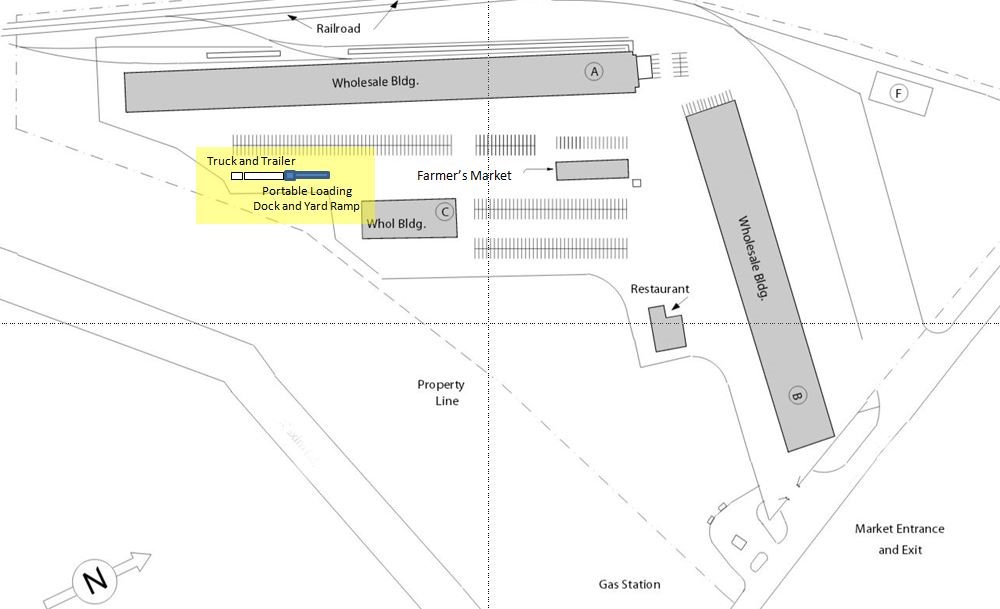

As pictured on the map above (highlighted in yellow), Handi-Ramp worked with the produce wholesaler to set up a portable loading dock ramp that was easily accessible to incoming trucks.

Handi-Ramp and the client agreed on a 36′ yard ramp that flattened off at the top, allowing for forklifts to comfortably access the truck trailer while rapidly loading and unloading trucks.

This ramp would be completely movable, but would be stationed near building C to allow for more direct forklift loading from trucks that would ordinarily lose time waiting for a dock in buildings A or B to open. The yard ramp could also be used to cut loading times for shipments from building C, and inbound shipments to the farmer’s market. The portability of the ramp also meant that, as demands for space and the volume of shipments changed, the ramp could be relocated to meet the demands of the facility.

The Results: HandiRamp’s Portable Yard Ramp Improves Efficiency, Cuts Spoilage, and Reduces Costs

Time Savings

Handi-Ramp’s portable loading dock significantly reduced the time drivers spent waiting for a shipping bay to open. Being able to flexibly unload more trucks meant less overtime for forklift operators and managers at the facility, reducing overheads and increasing employee morale.

Operational Efficiency

With the yard ramp also came an increase in the operational efficiency of building C. Shipping pallets were being staged in the immediate vicinity of the portable ramp. While building C is still handling local and smaller shipments, it’s doing so with a much higher degree of speed and efficiency, making it a central part of the client’s day-to-day operations.

Increased Productivity

With the ability to move the ramp wherever it’s needed and unload trucks anywhere on their campus, the client is enjoying an increase in manageability and productivity, and expects a sizable decrease in overheads over the next year.

Decreased Spoilage

Best of all, the addition of the portable loading dock to the produce wholesaler’s yard is projected to decrease spoilage by 4-7% over the course of the next year.

Ready to improve your property’s value and tenant satisfaction?

Interested? Call a Handi-Ramp Expert Today at 866-667-4884

Back to our main Yard Ramps page

Yard Ramp Knowledge BaseLearn More About Yard Ramps

Case Studies

Industry Resources

- Forklift Safety Requirements

- Modern Materials Handling

- Material Handling Product News

- Material Handling & Logistics