Yard Ramp Case Study: Manufacturing Park

Handi-Ramp Helps Replace Unsafe, Inconvenient Concrete Loading Ramp

About the Client:

• Business park home to a number of manufacturing companies

• Businesses share central yard for shipping/receiving

• All tenants share concrete, permanent ramp for loading and unloading

The Challenge:

• Concrete ramp is immoveable, unsafe

• Location of ramp inconvenient for some of the businesses in the park

• Sharing one ramp is causing delays for entire park

Solution:

• One business owner purchases portable yard ramp from Handi-Ramp

• Can use portability to safely meet his shipments anywhere in the yard

• Possible to rent yard ramp to other tenants

Results:

• Significant decrease in loading/offloading times at the complex

• Independence for the ramp’s owner

• Renters speed up their operations, stay safe – ramp owner collects rent

• Ramp quickly yields high ROI

Introduction

Larger manufacturing and business parks often have a difficult time coordinating an efficient shipping and receiving schedule, especially when there are numerous tenants vying for limited space in the same property. This was the situation at an industrial complex in a Northwest suburb of Chicago.

In an attempt to get the most out of the space available, the tenants of the complex shared a central shipping yard that also served as a parking lot. While each business had a designated loading area near their property, the space wasn’t large enough. Loading and unloading was a challenge.

The Challenge

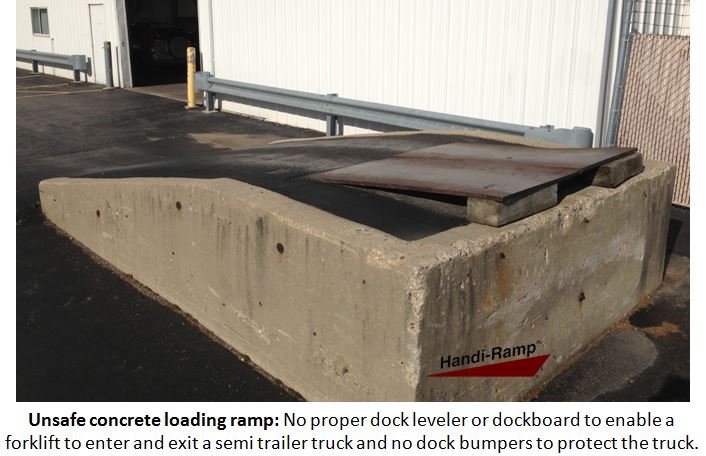

The concrete ramp (pictured here) was immovable, hastily built, and wasn’t positioned in the middle of the complex. This meant that businesses on the other end of the property were trekking across the large central yard just to unload goods, then hauling them across the yard to the back to their building.

Not only was the ramp fixed in place, but there were several safety issues as well. This ramp was an accident waiting to happen. The approach was uneven, the asphalt surface would become very slippery with the slightest amount of rain or snow, and there were no safety guard rails on either side of the ramp. With forklifts backing down the ramp, safety guard rails are a must to reduce the risk of a forklift driving off the ramp and flipping the forklift and load.

On the loading side of this ramp there was no proper transition between the truck and the ramp. This meant that whatever truck the businesses used to ship goods had to fit the height of the ramp. A dockboard or a loading dock leveler should have been used with this loading ramp to bridge the height difference. The bare metal plate used to transition between this ramp and the trucks wasn’t secured in any way, creating further risk for the forklift driver. And finally the dock side of this loading ramp should have had a dock bumper of some sort attached to protect the rear of the truck as it backs up to this concrete structure.

Our Solution

One of the business owners in the industrial park decided to try and resolve the problem themselves by purchasing a portable yard ramp, sparing themselves the hassle of both the central yard and the permanent, concrete ramp. Not only would this free up his receiving schedule from the collective one, but the portability would enable their business to meet any incoming shipments in whatever space they had available.

Additionally, if the ramp provided a significant enough advantage to their business, the owner of the ramp could rent out the ramp to some of the other tenants, turning his investment into an ongoing source of revenue. After searching for the best yard ramp providers, the business owner decided that Handi-Ramp was the only choice for the highest quality material handling products.

The Results

Handi-Ramp immediately shipped a 36′ portable yard ramp to the client. The business owner instantly saw a significant decrease in loading and offloading times for new materials. Not having to adhere to the complex receiving schedule meant they could operate on their own timetable, which saved time and allowed the business to form an efficient shipping/receiving strategy of their own.

The other tenants took notice of their fellow manufacturer’s increased productivity and sought to rent the ramp from its owner for each incoming shipment. With limited space to work with, the portability of the ramp was a massive advantage. Easily adjusted, the ramp turned the entire central yard into shipping and receiving space.

Anyone who rented the ramp saw the benefits and the ramp’s owner saw a rapid, significant return on investment (ROI) as he rented the ramp to his colleagues.

Interested? Call a Yard Ramp Expert Today at 866-667-4884

Back to our main Yard Ramps page

Yard Ramp Knowledge BaseLearn More About Yard Ramps

Case Studies

Industry Resources

- Forklift Safety Requirements

- Modern Materials Handling

- Material Handling Product News

- Material Handling & Logistics